What is WPC Wall Panel

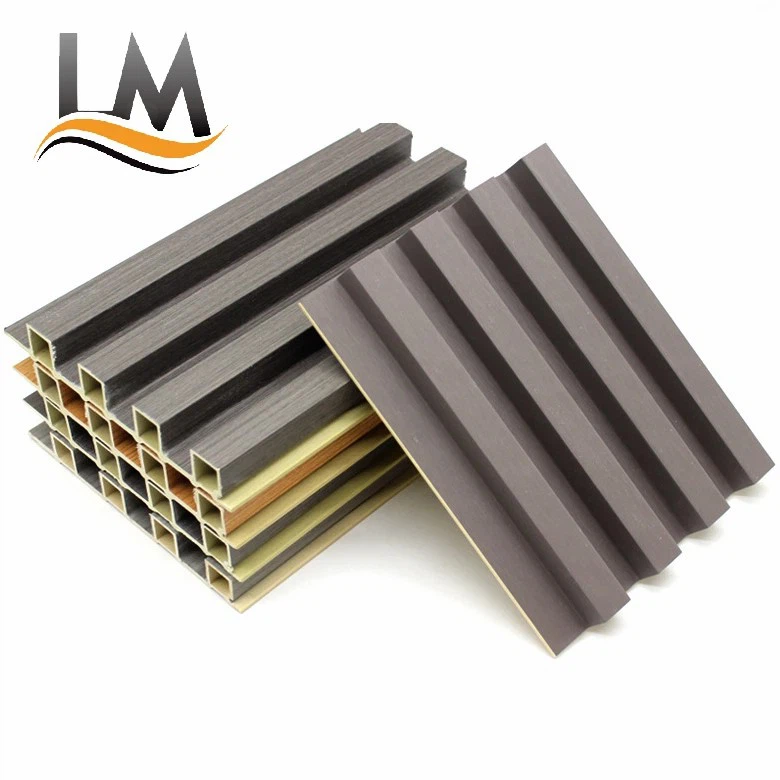

WPC wall panel stands for Wood Plastic Composite wall panel. It is a panel mainly made up of wood fibre and plastic. This combination of materials makes it an eco-friendly option for wall paneling. WPC wall panels are durable, low maintenance, and waterproof, making them ideal for use in areas like bathrooms, kitchens, and basements. They come in various colours, designs, and textures, making them suitable for different interior styles. WPC wall panels are easy to install and can be used in both residential and commercial spaces, making them a versatile option for interior design.

Advantages of WPC Wall Panel

Sound absorption

Common sound issues are caused mostly by sound waves reflecting off walls. The acoustical panel can absorb the noise in the room with its unique physical characteristic. Therefore, you don't worry about the noise issue if you decorate your room with the WPC wall panel with the sound absorption function.

Environmental-friendly

The WPC wall panel is made of the environmental raw material, the house installed won't have the chemical odor. You don't need to paint the WPC wall panel with oil to avoid pollution. So, you will save so much time without the painting process during the installation.

Easy installation

WPC wall panel s can be installed quickly, without any complicated installation steps. You can do diy while installing, the WPC wall panel can be cut into the size you want to decorate the wall to be perfect. You don't need to hire a labor-saving time and money at the same time.

Modern styles

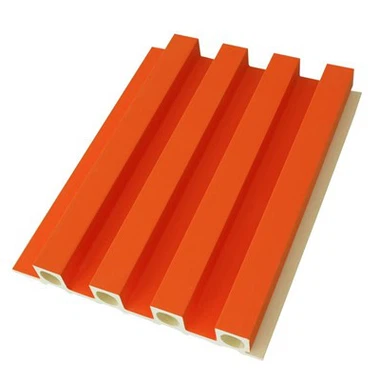

Above all, the WPC wall panel has various colors, shapes, patterns, you can choose the style matching your room. A well-designed WPC wall panel can decorate your wall with the high valued aesthetics. You can assembly the WPC wall panel following your own ideas.

Why Choose US

One-stop solution

With rich experience and one-to-one service,we can help you choose products and answer technical questions.

Customization services

They provide customization services to meet specific customer requirements, ensuring that clients receive products that exactly fit their needs.

Innovation

We are dedicated to improving our systems continually, ensuring that the technology we offer is always cutting edge.

24h online service

We try and respond to all concerns within 24 hours and our teams are always at your disposal in case of any emergencies.

The Difference Between Wpc Wall Panels And Pvc Wall Panels

Material composition

WPC wall panels are made of a combination of wood fibers and thermoplastics. The wood fibers used in WPC panels are usually recycled wood.

PVC wall panels are made of 100% rigid plastic & PVC resin (polyvinyl chloride), the plastic resins are made of virgin PVC.

Appearance

WPC wall panels have a more natural wood-like appearance, with visible wood grains and texture.

PVC wall panels have a smooth, glossy surface with no visible texture, which has a more plastic-like appearance.

Installation method

WPC wall panels can be installed using a variety of methods, including tongue and groove, clip and screw, and adhesive.

PVC wall panels are easier to install than WPC wall panels, as they are typically installed using adhesive only.

Thickness

WPC wall panels are thicker than PVC wall panels, which makes them more durable and resistant to impact.

WPC wall panels also come in various thicknesses, depending on the manufacturer and intended use. Common thicknesses for WPC wall panels include:

8mm - Suitable for interior residential and commercial applications, like living rooms, bedrooms, and offices. This thickness provides a good balance between durability and affordability.

10mm -A more robust option, offering increased durability and insulation. These are often used in commercial or high-traffic residential areas where greater resistance to wear and tear is needed.

12mm - These panels are designed for heavy-duty applications, such as exterior cladding or commercial environments, where additional strength and durability are required.

15mm - The thickest panels are typically used in special applications, where extreme durability and insulation are needed, such as in exterior cladding for buildings or other demanding environments.

Please note that these are general guidelines, and specific products may vary. It's essential to choose the right thickness for your specific application and consult the manufacturer's recommendations.

PVC wall panels come in a variety of thicknesses, depending on their intended use and the specific product. Common thicknesses for PVC wall panels include:

5mm - Commonly used for interior residential and commercial applications, like bathrooms and kitchens. This thickness provides a balance between durability, cost-effectiveness, and ease of installation.

8mm - A slightly thicker option, offering increased durability and insulation. These are often used in commercial or high-traffic residential areas where greater resistance to wear and tear is needed.

10mm - These panels are designed for heavy-duty applications, such as industrial or commercial environments, where additional strength and durability are required.

12mm - The thickest panels are typically used in special applications, where extreme durability and insulation are needed, such as in cold storage facilities or industrial settings.

Keep in mind that these are general guidelines, and specific products may vary. It's important to choose the right thickness for your specific application and consult the manufacturer's recommendations.

Weight

WPC wall panels are heavier than PVC wall panels, which makes them more difficult to install.

PVC wall panels are lighter than WPC wall panels, making them easier to install.

Fire resistance

Both WPC and PVC wall panels are fire-resistant, but WPC panels are more resistant to flames and heat.

PVC wall panels are less fire-resistant than WPC wall panels, as PVC has a low ignition point.

UV resistance

WPC wall panels are more resistant to UV radiation than PVC wall panels, which makes them ideal for use in outdoor applications.

PVC wall panels are less UV-resistant than WPC wall panels, but it does not fade or discolor as easily as WPC.

Moisture & Water resistance

WPC wall panels are more water-resistant than PVC wall panels due to the presence of wood fibers, which absorb moisture and prevent warping, which makes them ideal for use in high-humidity environments.

PVC wall panels are also water-resistant but it does not absorb moisture.

Resistance to chemicals

WPC wall panels are less resistant to chemicals as they can be damaged by certain chemicals.

PVC wall panels are more resistant to chemicals than WPC wall panels, which makes them ideal for use in industrial and laboratory settings.

Scratch resistance

WPC wall panels are less scratch resistant than PVC panels.

PVC wall panels are more scratch-resistant than WPC wall panels.

WPC wall panel is made of wood chips, bamboo chips, rice husks, rice bran, peanut husks, cotton straws and other low-plant biomass fibers as the main raw materials. WPC wall panel uses the principle of polymer interface chemistry and the characteristics of plastic filling and modification to mix a certain proportion of plastic base materials., a wall decoration material processed and formed after special processing. So, WPC wall panel for walls has some properties of plastic and wood. It has the characteristics of reversible recycling, wide-coverage, various product types and various morphological structures.

Because of the unique nature of the WPC wall panel, it can make all the board shapes on the market, such as flat shape, wave shape, grid shape, and special shape. Different shapes can also be matched, and the style is more unique.

What are the Applications of WPC Wall Panel

Wall cladding

WPC wall panels are an excellent alternative to traditional building materials such as wood, metal, and concrete. These WPC wall panels are commonly used for wall cladding in both residential and commercial buildings. They offer an attractive, natural wood look and feel, while also providing durability and resistance to weathering, moisture, and insects.

Ceilings

WPC wall panels can be used as ceiling tiles or panels in a variety of indoor and outdoor settings. They offer an excellent acoustic performance, reduce noise levels and enhance the aesthetic appeal of any space. WPC wall panels require very little maintenance. Unlike traditional wood that require regular painting, staining, or sealing.

Furniture

WPC wall panels are used to create furniture such as chairs, tables, and cabinets. They are durable, lightweight and can be molded into different shapes and sizes, making them ideal for furniture design. And it is resistant to deformation, moisture, and insects and waterproof, and has certain environmental protection properties.

Flooring materials

The WPC wall panels are also used as flooring materials, particularly in high-traffic areas such as commercial spaces, patios, and decks. WPC panels are resistant to fading, cracking, and warping. They are easy to clean and maintain, needing only periodic washing with soap and water to maintain their appearance. They are slip-resistant and easy to clean, making them a popular choice for outdoor flooring.

Decking materials

WPC wall panels are also used as decking materials for outdoor spaces such as patios, balconies, and pool areas. They are highly resistant to weathering, moisture, and insects, making them a popular and long-lasting alternative to traditional wood decking.

Comparison of WPC and MDF Wall Panels

Here are some key factors to consider when comparing WPC and MDF wall panels:

Durability: WPC wall panels are highly durable and weather-resistant, making them ideal for outdoor or moisture exposed area. MDF panels are less resistant to moisture and decay and may require regular maintenance.

Installation: WPC panels can be installed using a clip and rail system, which makes them easy to install and remove. MDF panels installation involves nailing or gluing them to the wall.

Aesthetics: WPC panels come in a range of colors and textures, including wood grain patterns, while MDF panels can be painted or covered with a veneer to create a variety of finishes.

Cost: WPC panels are generally more expensive than MDF panels, but they offer superior durability and weather resistance. WPC cost per sqm is approximately ~4400php/sqm with surface finish while MDF cost per sqm is ~2000php/sqm with paint or lamination.

Versatility: The flexible nature of MDF panel allows it to fit more shape or surface, making it a versatile solution for a wide range of applications. While WPC with its hardness is more restricted in linear application.

How to Install WPC Wall Panels on a Wall

Part 1: Preparation

Materials and tools required

Before diving into the installation process, it's crucial to gather all necessary materials and tools. Here's what you'll need:

- WPC wall panels

- Measuring tape

- Level

- Drill

- Screws and wall plugs

- Saw (hand saw or power saw)

- Safety equipment (gloves, goggles)

- Adhesive (optional, depending on installation method)

Measuring and Planning

Proper measurement and planning are the foundations of a successful installation. Begin by measuring the dimensions of your wall to determine the number of panels required. It's always a good idea to purchase a little extra to account for any mistakes or adjustments.

Next, plan the layout of your panels. Decide whether you want a horizontal or vertical orientation. Consider any obstacles on the wall, like sockets or switches, and plan how you'll navigate these with your panels.

Part 2: Pre-installation preparation

Cleaning the wall

A clean, smooth surface is essential for a flawless installation. Start by removing any existing wall coverings, nails, or screws. Fill in holes or cracks and sand down any uneven areas. Finally, clean the wall thoroughly to remove dust and debris.

Setting up guide lines

To ensure your panels are aligned correctly, set up horizontal and vertical guide lines using a level. These lines will act as a reference throughout the installation process, helping you to maintain a straight and consistent layout.

Part 3: Installing WPC wall panels

Fixing the starter panel

The installation process begins with the starter panel. This is a crucial step as it sets the tone for the rest of the panels. Align the first panel with your guide lines, ensuring it's perfectly level. If your panels have a tongue and groove system, make sure the tongue side is facing up or towards the direction you will continue installing. Secure the panel to the wall using screws, drilling them into the wall studs for a firm hold.

Sequential installation

After the first panel is in place, continue with the next one, fitting it into the groove of the starter panel. Apply gentle pressure to ensure a tight fit. For additional support, you can use adhesive along with screws. Continue this process, ensuring each panel is level and flush with the previous one. Remember to stagger the joints for a more natural and aesthetically pleasing look.

Handling corners and edges

Corners and edges require special attention. Measure and cut the panels to fit these areas precisely. If your room has inside corners, you may need to use corner trims for a neat finish. For outside corners, miter cutting the panels for a seamless join is an effective approach.

Part 4: Finishing touches and maintenance

Caulking and sanding

Once all panels are installed, inspect the wall for any gaps or seams. Use caulk to fill these in for a smooth, uniform appearance. If necessary, lightly sand the surface for a flawless finish. Be sure to clean off any dust or debris afterward.

Cleaning and maintenance

WPC wall panels are low maintenance, but regular cleaning will keep them looking their best. Use a soft cloth and a mild detergent solution to wipe them down. Avoid using abrasive cleaners or scrubbers that could damage the surface.

FAQ

We're professional WPC wall panel manufacturers and suppliers in China, specialized in providing high quality customized service. Please feel free to wholesale cheap WPC wall panel for sale here from our factory. Good service and low price are available.

Wooden Cladding for Wall Decoration, Water Proof Wood Plastic Composite Cladding, WPC Wall Panel