Description

Technical Parameters

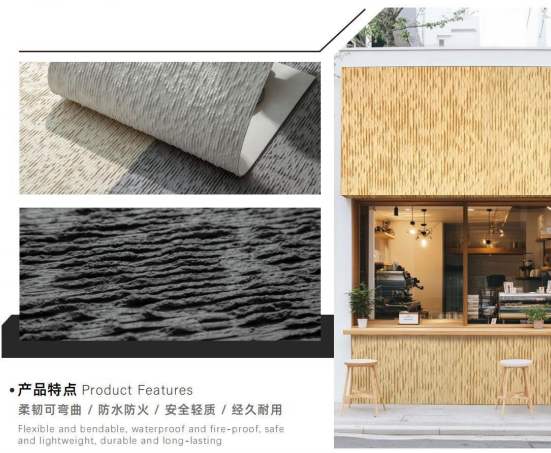

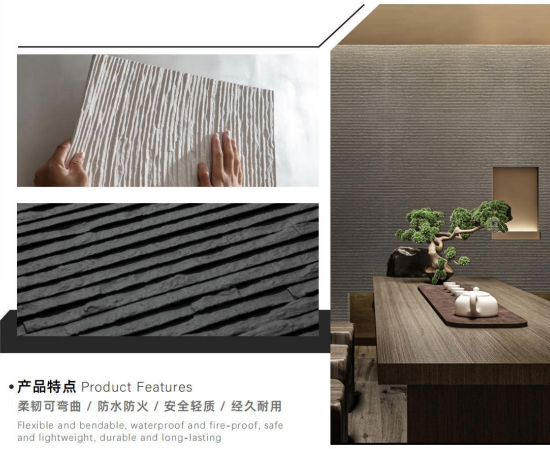

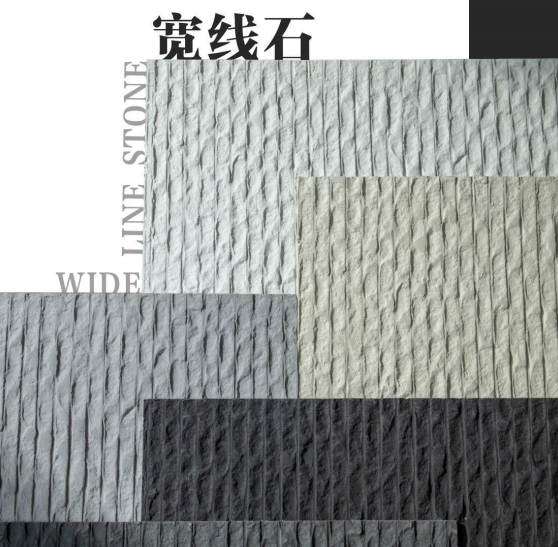

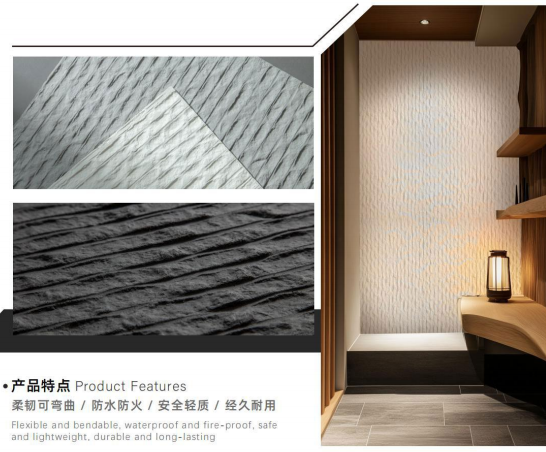

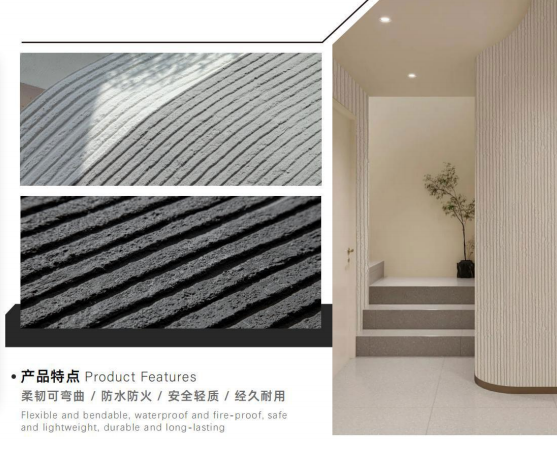

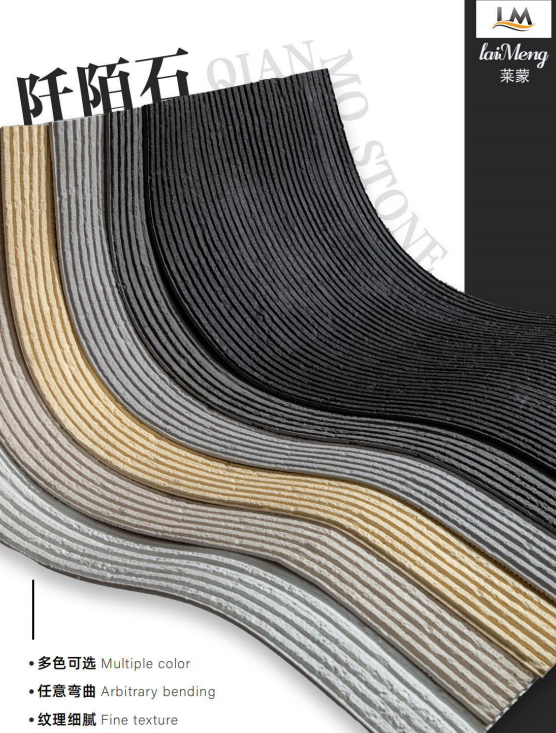

Products Description

The production process of soft porcelain (flexible tiles or flexible stone) is a relatively complex process, involving multiple steps and key technologies. The following are the main production processes of soft porcelain:

1. Preparation of raw materials

- Main raw materials: modified soil (MCM), inorganic mineral powder (such as mud powder, stone powder, etc.), environmentally friendly water-soluble architectural coatings.

- Auxiliary materials: adhesives, pigments, additives, etc.

2. Mix and stir

- Ingredients: Weigh various raw materials according to a certain proportion according to the formula and put them into the mixing equipment.

- Stirring: Use a high-speed mixer to mix the raw materials evenly to ensure that the ingredients are evenly distributed.

3. Forming

- Mold preparation: Prepare the corresponding mold according to the required product shape and size.

- Extrusion molding: The mixed raw materials are extruded through the extruder to form continuous sheets or strips.

- Pressing and molding: For products that require specific textures or patterns, pressing equipment can be used for pressing and molding.

4. Dry

- Preliminary drying: Place the molded soft porcelain sheets or strips in a well-ventilated environment for preliminary drying to remove excess moisture.

- Drying: Send the initially dried soft porcelain into the drying equipment and dry it at a specific temperature to cure it.

5. Surface treatment

- Sandblasting: Sandblasting of dried soft porcelain to increase the texture and roughness of the surface.

- Sanding: Use sanding equipment to sand the surface to make it smoother.

- Painting: According to the design requirements, the soft porcelain is sprayed or rolled with environmentally friendly water-soluble architectural paint to give it the required colors and textures.

six. Bake

- High-temperature baking: The surface-treated soft porcelain is sent to the high-temperature baking oven and baked at a specific temperature to further cure the material and enhance its performance.

- Cooling: After baking, take out the soft porcelain and cool it naturally to room temperature.

seven. Irradiation cross-linking

- Irradiation treatment: The cooled soft porcelain is sent into the irradiation equipment, and cross-linked by high-energy rays (such as ultraviolet or electron beams) to further improve the strength and durability of the material.

- Secondary cooling: Cooling again after irradiation treatment to ensure that the material is completely cured.

8. Quality inspection

- Appearance inspection: Check whether the surface of soft porcelain is flat, free of cracks, bubbles and other defects.

- Size measurement: Use measuring tools to accurately measure the size of soft porcelain to ensure that it meets the standard.

- Performance test: Carry out a series of performance tests, including flexibility, tensile strength, waterproofness, weather resistance, etc., to ensure that the product quality meets the standard.

9. Packaging and storage

- Packaging: Qualified soft porcelain products are packaged, usually using moisture-proof and dustproof packaging materials.

- Storage: Store the packaged soft porcelain in a dry and ventilated warehouse, avoiding direct sunlight and humid environment.

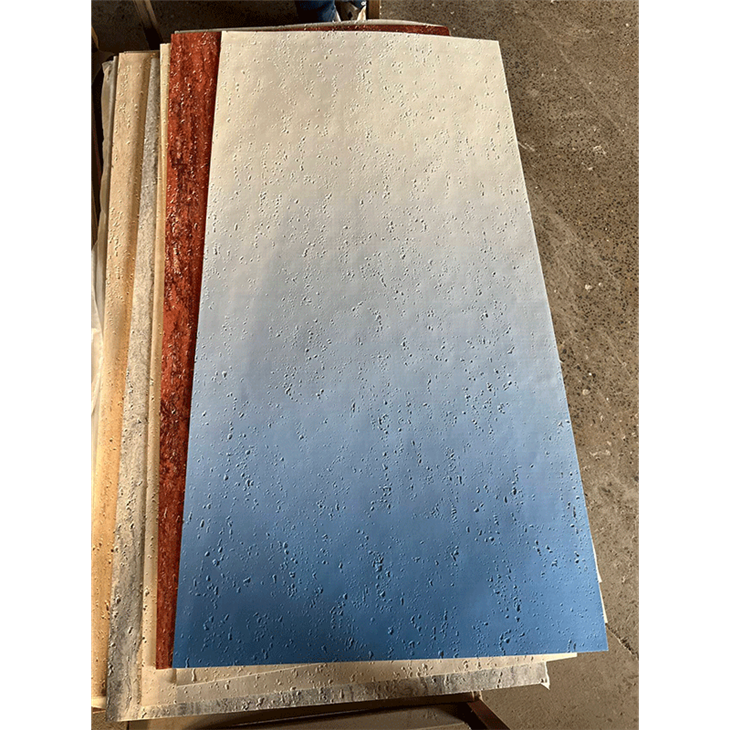

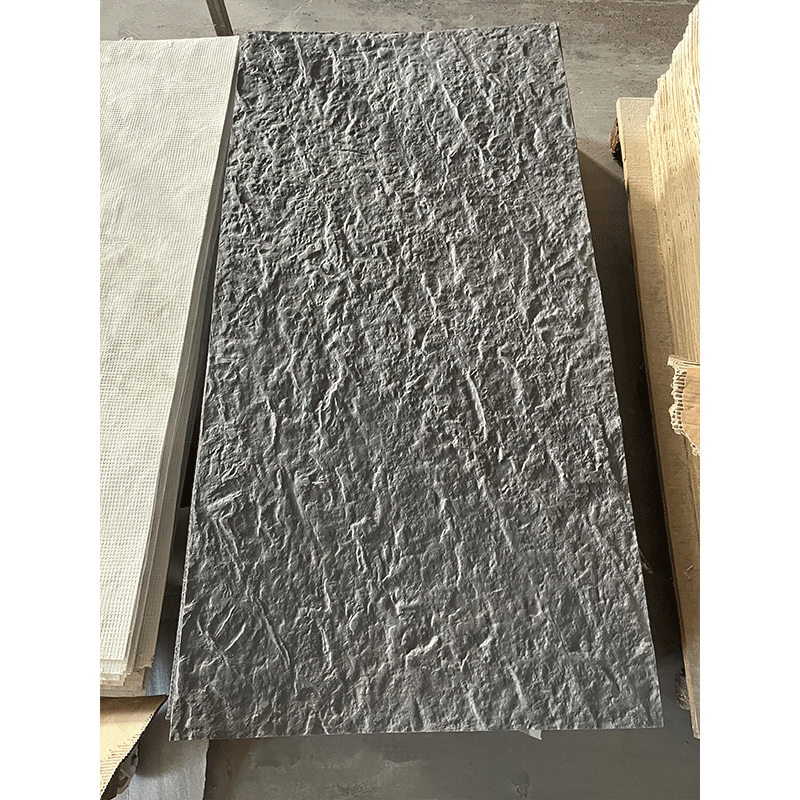

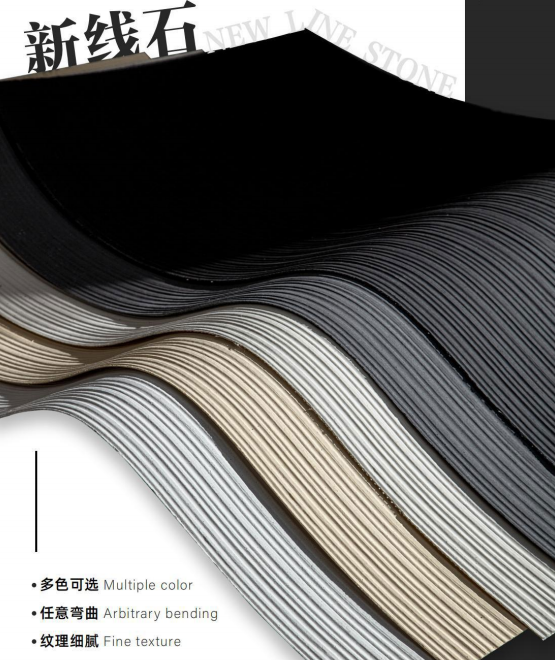

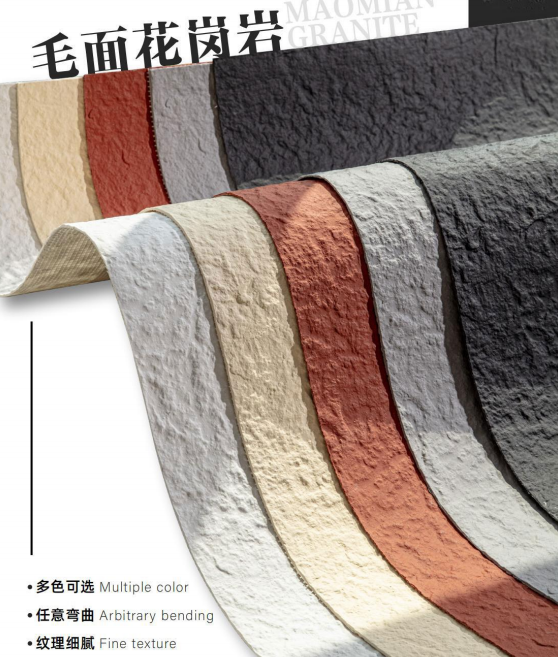

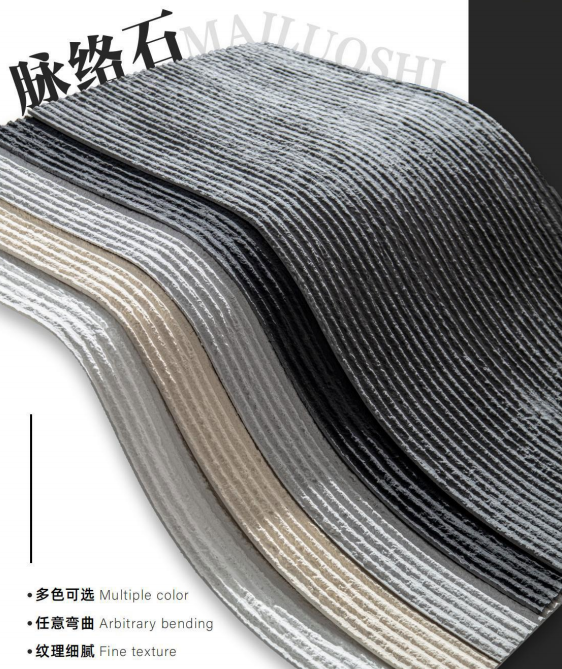

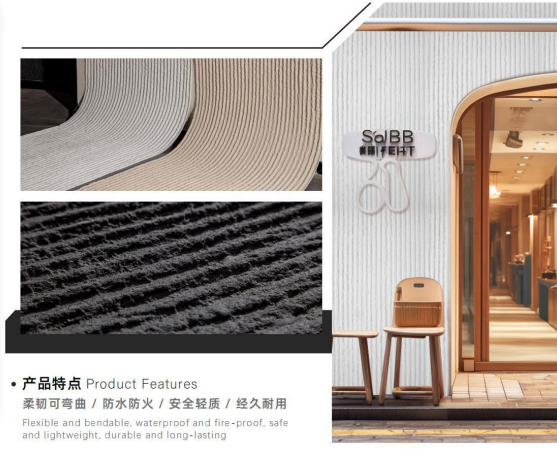

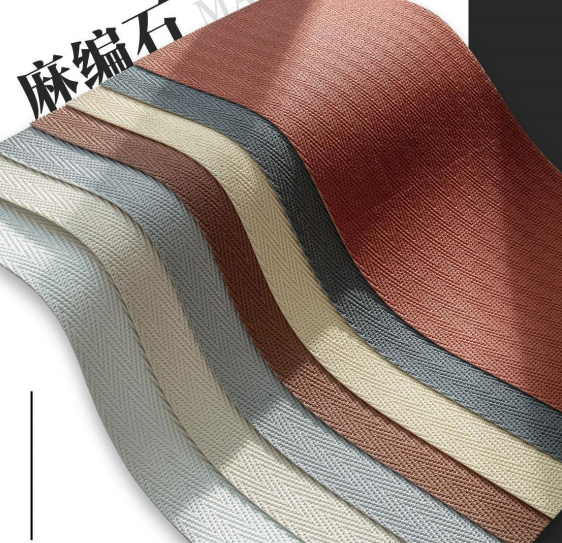

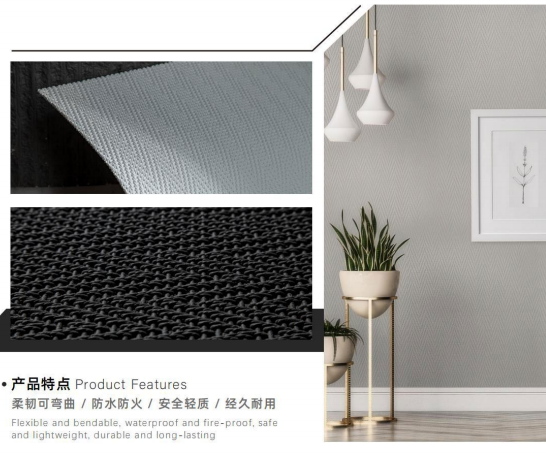

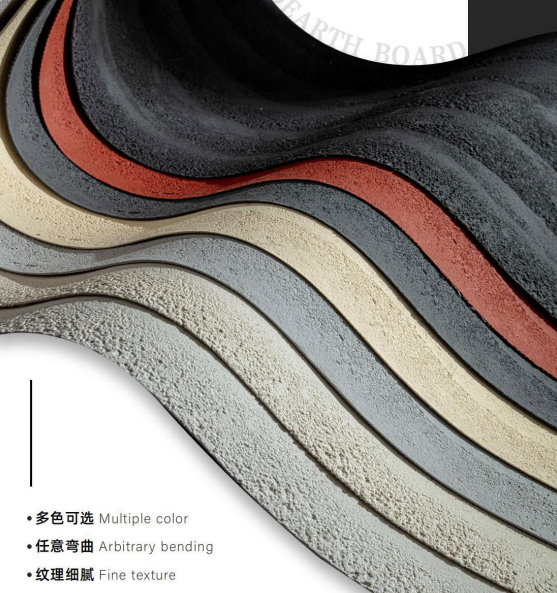

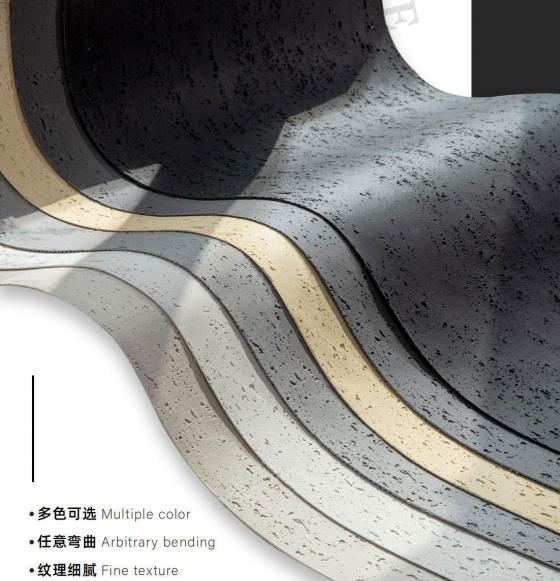

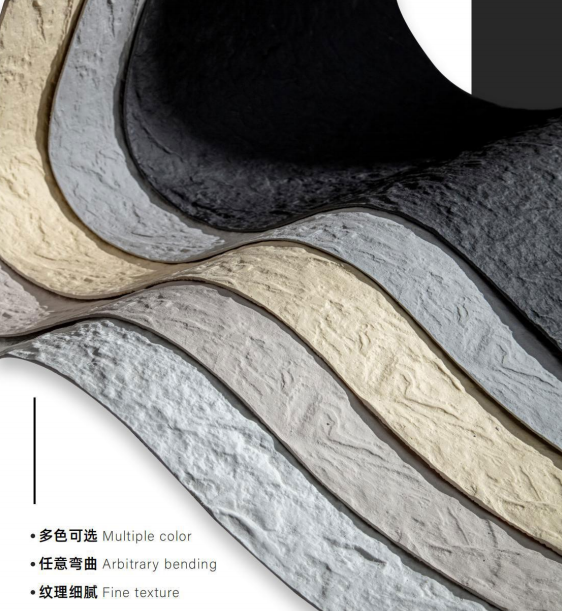

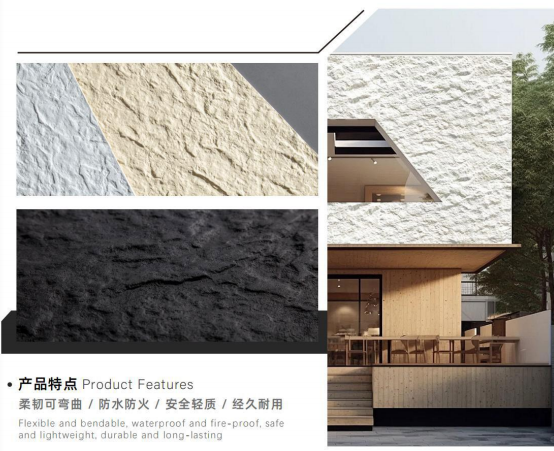

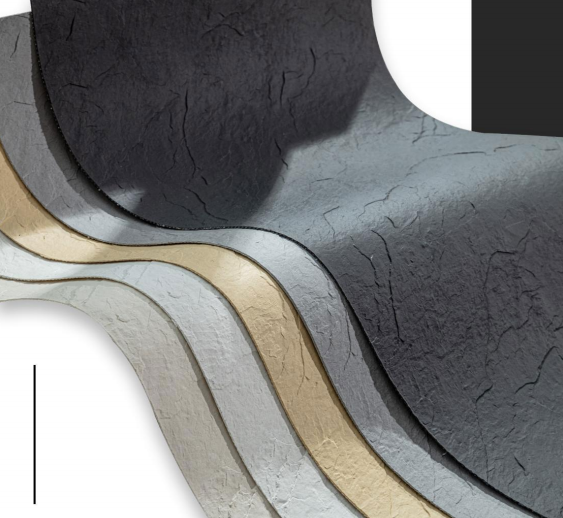

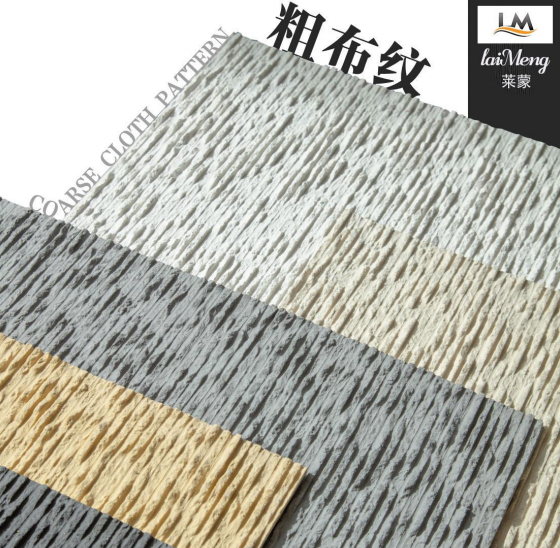

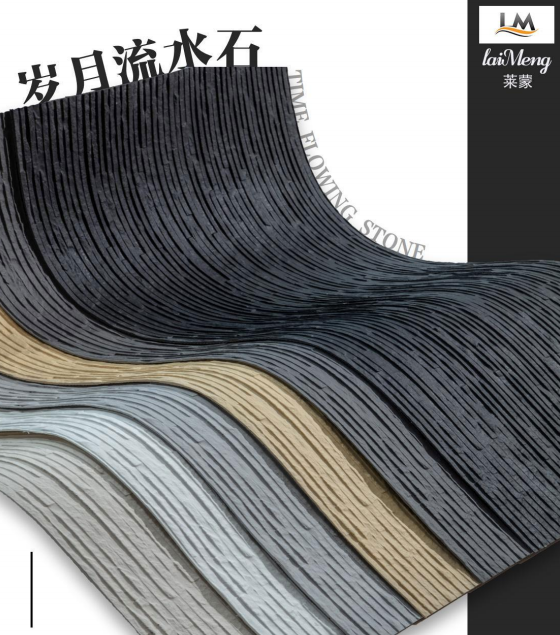

Products Display

Our Factory

Hot Tags: Soft Stone Wall Panel, China Soft Stone Wall Panel manufacturers, suppliers, factory, Wood Substitute, Ps Charcoal Board, 3mm Flexible Plastic Marble Sheet, Wooden Cladding for Wall Decoration, Interior WPC Wall Panels, WPC Wood Plastic Composite Wall Panel

Previous

Soft PorcelainSend Inquiry