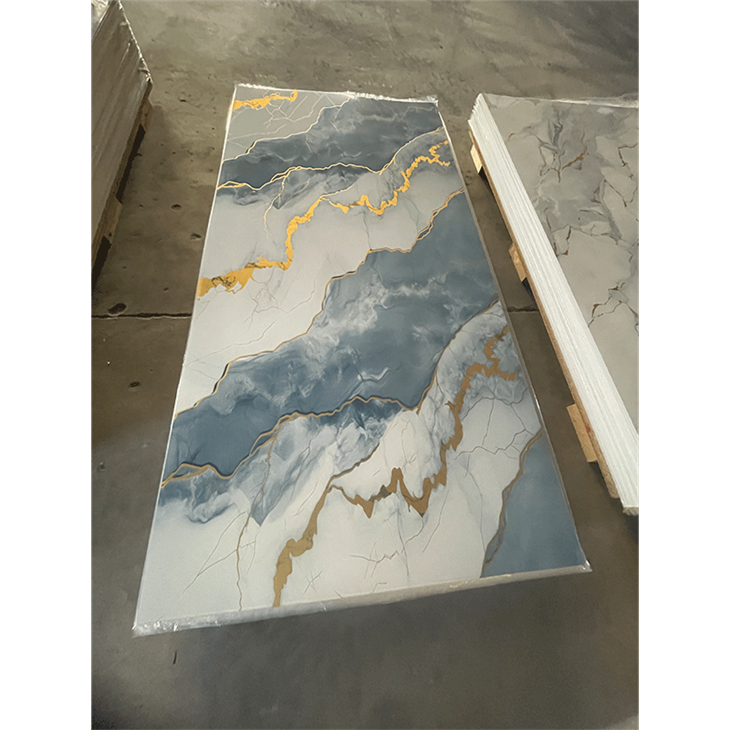

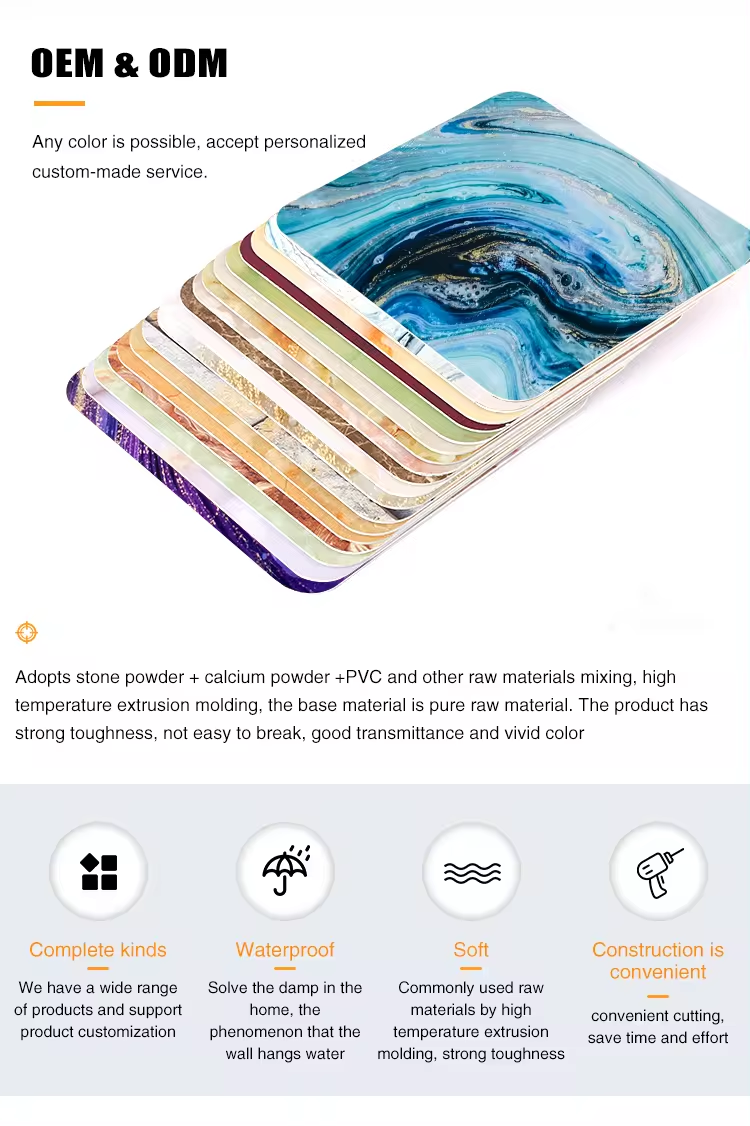

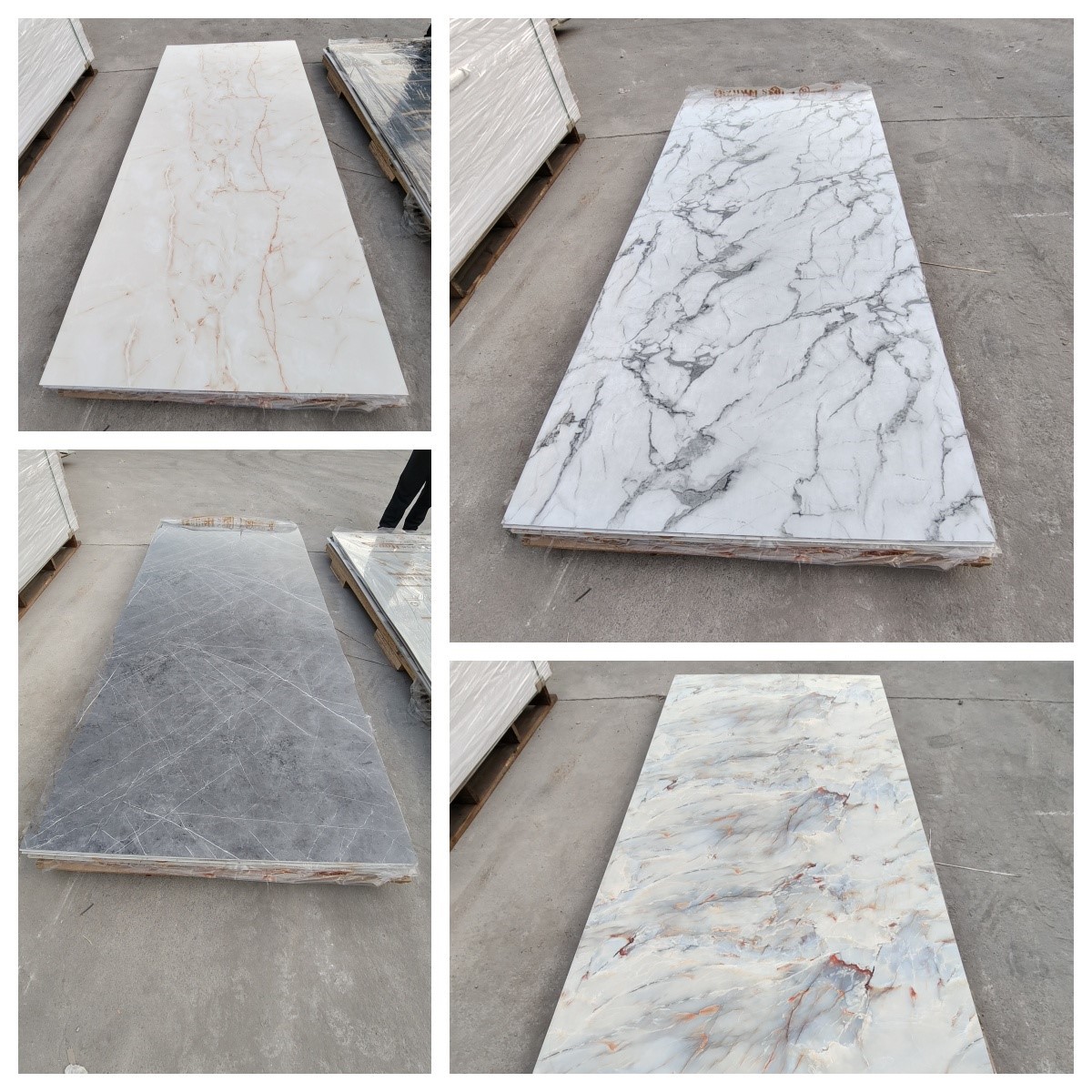

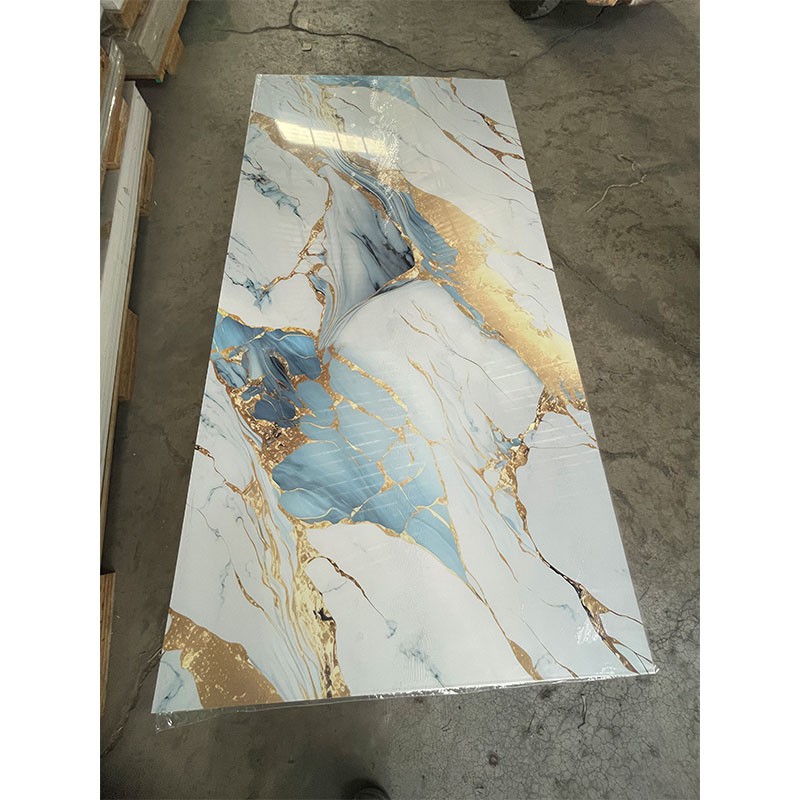

Description

Technical Parameters

Products made of marble and PVC have their own advantages and disadvantages. The following is a comparison of some aspects:

Physical properties:

Marble:

Advantages: dense structure, high hardness, good rigidity, not easy to crack and deform, good compressive strength and wear resistance, strong physical stability, extremely small linear expansion coefficient, small temperature deformation, stable plane, and non-magnetization. The texture of marble is natural and beautiful, and the texture is heavy, which can give people a noble and elegant feeling.

Disadvantages: The texture of marble is relatively brittle and is easily damaged when it is pressed by sharp objects or hit hard. Its Mohs hardness is between 3-5, which is not particularly high. It will gradually lose its luster, fade, and even crack when exposed to outdoor conditions for a long time, and its service life is relatively short.

PVC:

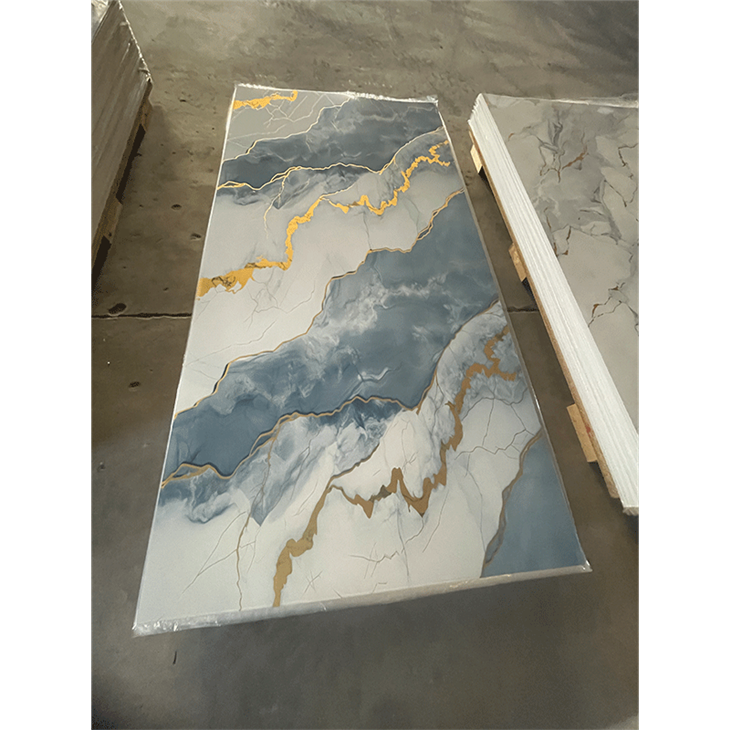

Advantages: It has good strength and toughness, good adaptability to the external environment, and is not easy to break. Its material is relatively light, and it is easy to carry and install.

Disadvantages: Soft PVC products are easy to become brittle and difficult to preserve; hard PVC may appear whitening at bends. And its surface hardness is not as good as marble, and it is easy to be scratched.

Chemical properties:

Marble: The main component is calcium carbonate, which is weakly alkaline. Its chemical properties are relatively stable, but it is easily corroded by acids. For example, strong acids such as hydrochloric acid and sulfuric acid will react with marble, causing damage to its surface.

PVC: It has strong resistance to oxidants, reducing agents and strong acids, but can be corroded by concentrated oxidizing acids such as concentrated sulfuric acid and concentrated nitric acid, and is not suitable for contact with aromatic hydrocarbons and chlorinated hydrocarbons.

Processing difficulty and cost:

Marble: The processing of marble requires professional equipment and technology, which is difficult and costly. Especially when fine processing such as carving and polishing of marble is carried out, a lot of manpower and material resources are required.

PVC: The processing is relatively simple, and it can be processed by injection molding, extrusion, calendering and other methods, with high production efficiency and relatively low cost.

For more details,Please contact Lilian(WhatsApp):+8615206832922

Hot Tags: 1220mm width 2800mm length pvc marble sheet, China 1220mm width 2800mm length pvc marble sheet manufacturers, suppliers, factory, PVC Marble Sheet, Ps Decorative Wall Panel, Flexible Uv Marble Sheet, Composite Ceiling Panel, Marble Replacement, 3mm Flexible Plastic Marble Sheet

Previous

PVC Marble Alternative PanelSend Inquiry